Screen printing services in Canada.

Polar Promotions is a leading choice for custom silk screen printing in Canada. Screen printing stands as a time-tested and reliable method for imprinting designs onto clothing. Our 10,000 square foot Calgary production facility boasts a blend of automatic and manual screen printing machines, a choice favoured by over 70% of our clientele due to its cost-effectiveness in large-scale productions and its ability to produce vibrant prints. Not located in Alberta? No problem! We have decoration partners across the country.

What promotional products can be screen printed?

While clothing items such as custom t-shirts, hoodies, and caps are popular choices for screen printing in Canada, the versatility of this printing method allows it to be applied to a wide range of promotional items. Some examples of promotional products that can be screen printed include.

Want to see more? click the link below to visit our shop.

Let's go shopping!How does screen printing work?

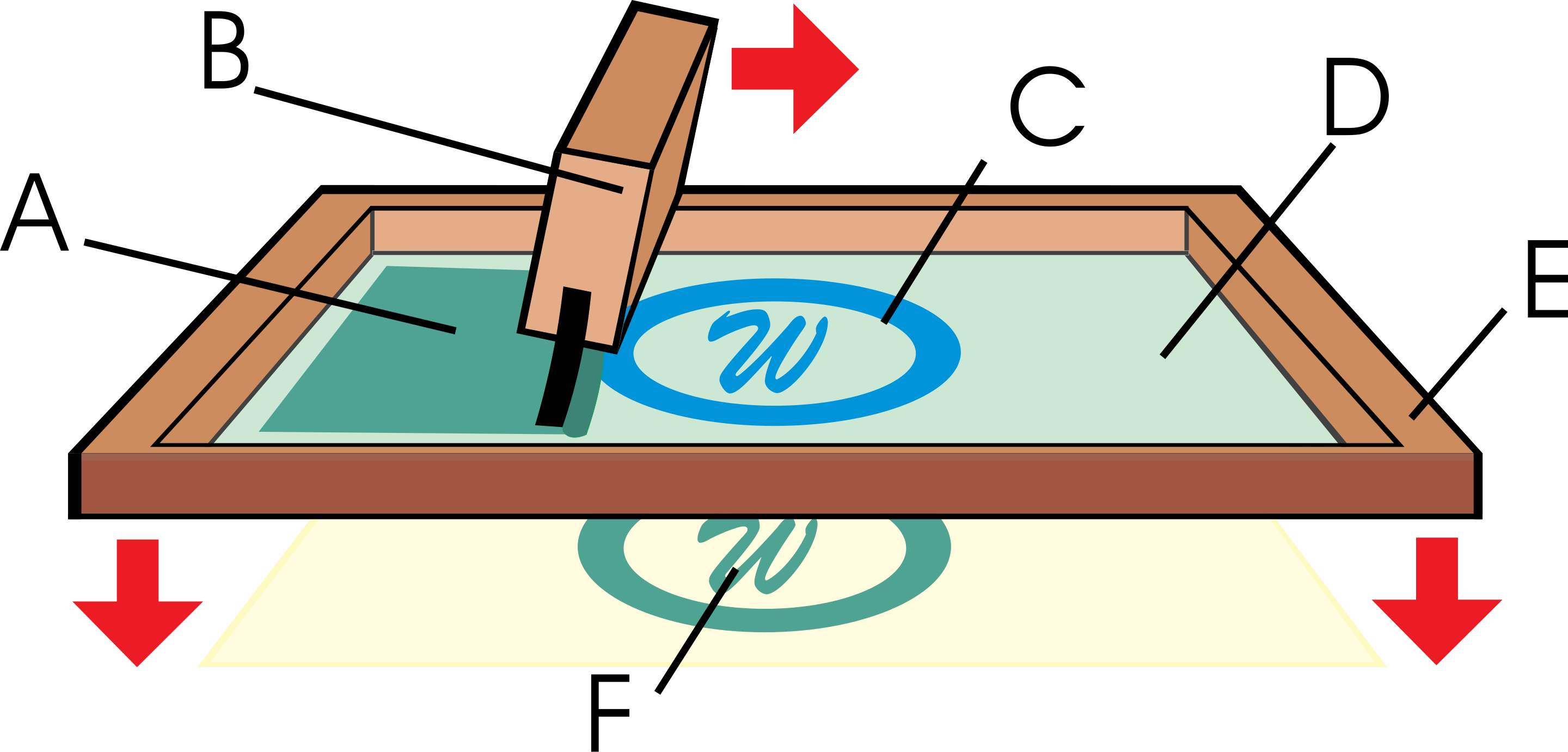

In screen printing, ink(A) is systematically pushed with a squeegee(B) through a designated image(C) of photo-emulsion(D) areas of a screen(E), resulting in your desired printed image(F).

A. Ink B. Squeegee C. Image D. Photo -emulsion E. Screen F. Printed Image

What are the benefits of screen printing?

There are a number of benefits to screen printing, there is a reason why it is one of the most popular printing methods available.

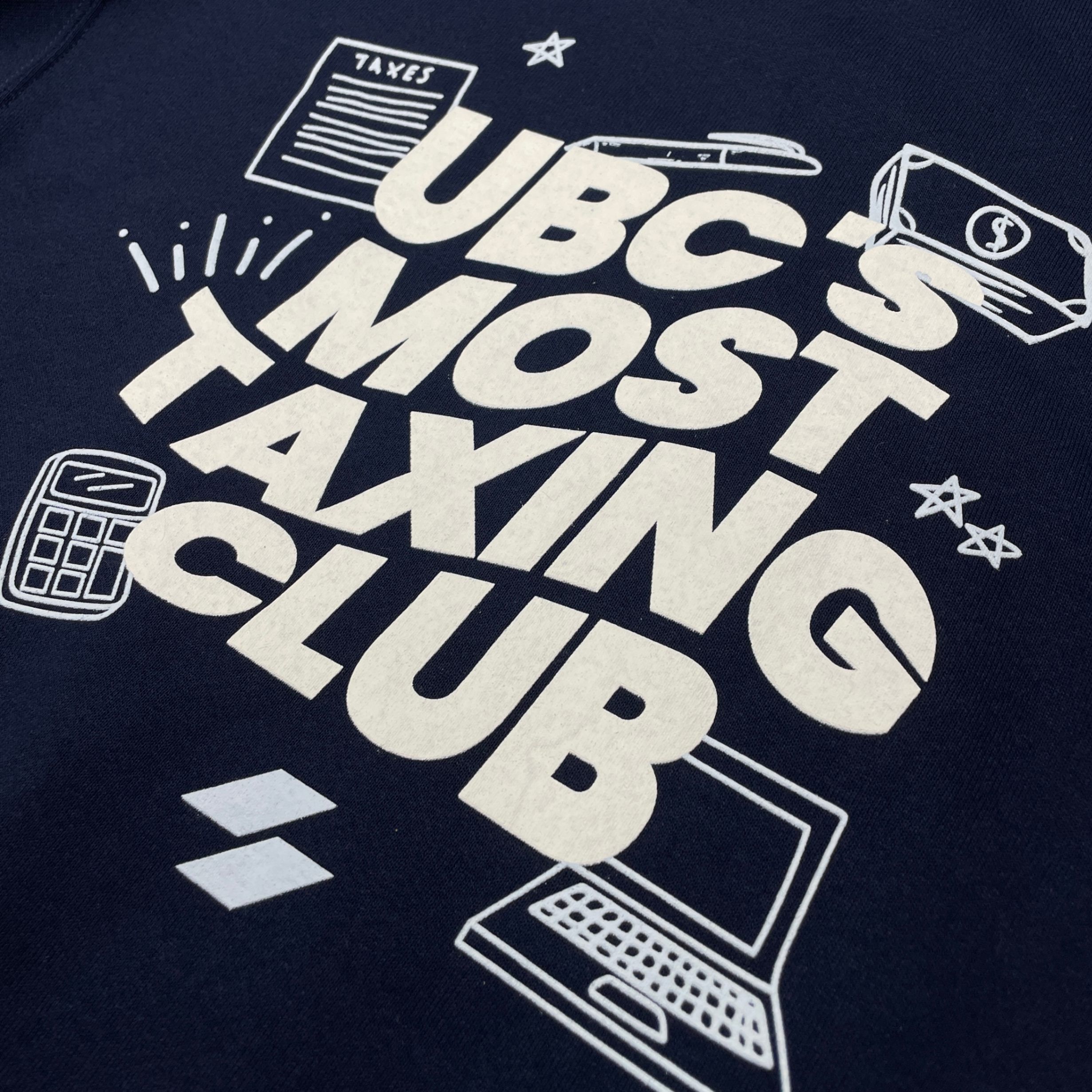

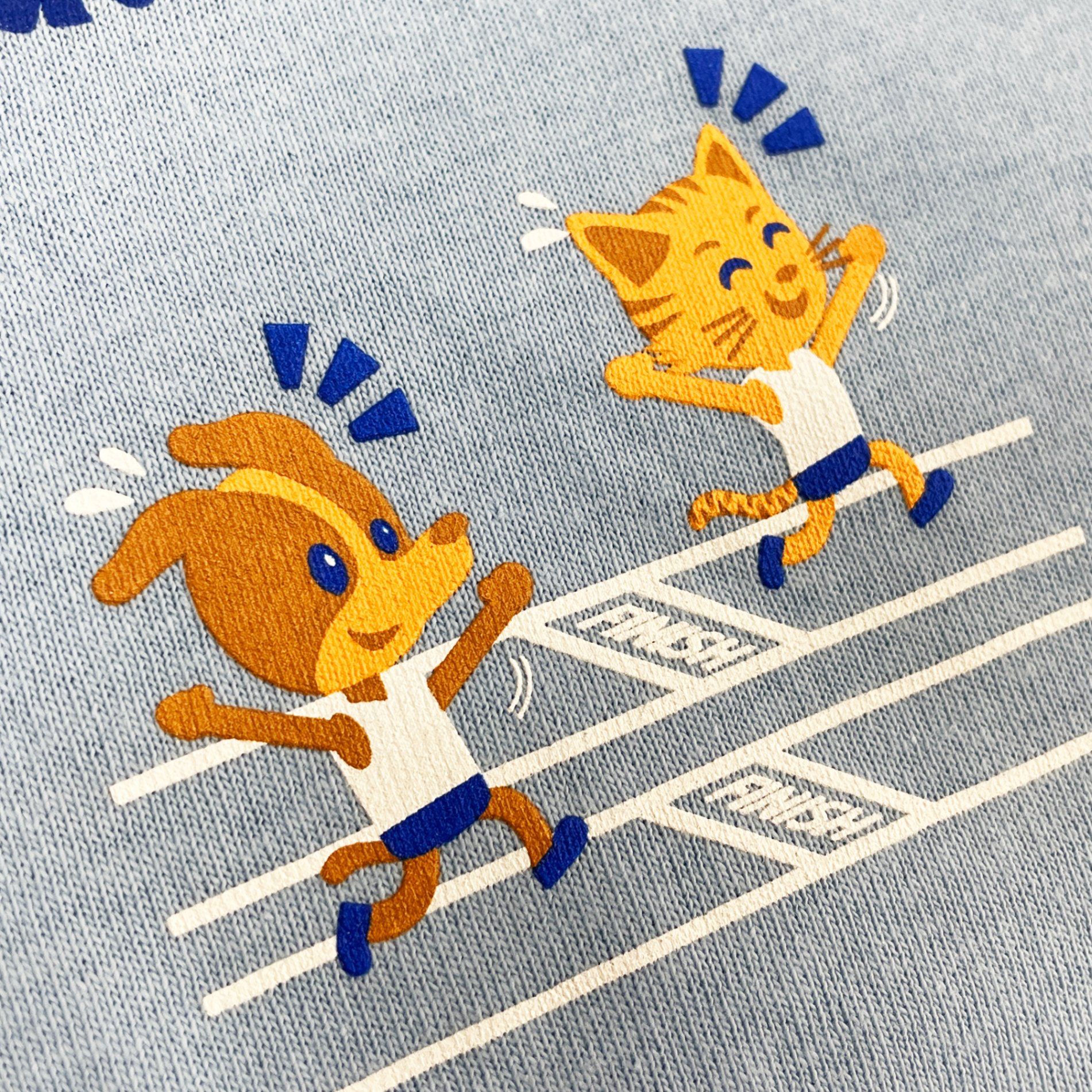

Screen printing results in vibrant colours.

- Screen printing results in vibrant colours that pop every time. Unless you request for a vintage screen print, we typically under base all of our screen prints with a white layer and apply colours on top to ensure vibrancy.

Screen printing services is low cost at higher quantities.

- At higher quantities, screen printing is a cost-effective print method.

Screen printing last a long time.

- Screen prints are made to last. After a screen print is run through our conveyor dryer it leaves fully cured and ready to be worn, washed and used repeatedly.

Does screen printing have limitations?

Surface constraints.

- Screen printing needs a flat surface for printing, restricting the ability to print on irregular areas like seams. As a result, achieving an “all-around print” is not feasible. For such intricate prints, we recommend exploring sublimation printing for optimal results.

Size Restrictions.

- Our screen printing process accommodates a maximum print size of 14 x 17 inches, ensuring quality and precision within these dimensions.

Colour Complexity.

- With our machinery limited to 8 colours, intricate designs with more than 8 colours may pose a challenge. In such cases, alternatives like DFT or sublimation printing offer greater flexibility and colour depth.

Cost Considerations for Small Runs.

- While ideal for larger orders, screen printing’s setup requirements make it less cost-effective for smaller runs. For instance, executing a screen print on both the front and back of a single shirt can escalate costs significantly, potentially reaching up to $100 for the entire order. To mitigate expenses, we recommend exploring alternative printing methods such as DFT printing for smaller quantities.

By understanding these limitations, you can make informed decisions regarding your printing needs. Contact us to explore the best printing solution tailored to your project. We are happy to help.

Screen print FAQ.

What is the difference between embroidery and silk screen?

- Heat transfer involves using heat to apply pre-printed designs onto surfaces, while silk screen printing uses stencils to apply ink directly onto surfaces. Heat transfer is simpler and better for intricate designs but less durable, while silk screen printing is more durable and suited for larger quantities with simpler designs.

What type of emulsion is screen printing?

- Screen printing primarily employs photosensitive emulsion, which hardens when exposed to light. This emulsion is applied to the screen and used to create a stencil for printing designs onto substrates.

What is the best t-shirt printing method?

- Ultimately, the best method depends on your specific needs, considering factors like design complexity, quantity, budget, and desired durability. We recommend connecting with a rep to get started.

Ready to get started?

Fill the form below and a team member will respond within 24 hours.